Let us first recall what this is about. The Green Wave is a concept that every driver in the city knows well. It is the synchronization of green lights on a one-way street. If the lights are synchronized for a vehicle traveling at 20mi/h for example, when this vehicle starts at a green light and travels at an average of 20mi/h, the traffic lights turn green when it arrives at an intersection.

Green Wave Planning in Manufacturing, a division by 5 of the WIP (work in process stock).

In Manufacturing, the Green Wave is similarly a production planning and scheduling mechanism that means that when a batch of products arrives in front of a production unit, the production unit is finishing the preceding batch. The production units (machine, workshop, operators) are synchronized to be available when they are needed. This is what happens when you have timed production lines, such as packaging lines for example, bottling lines or car assembly lines. These are sophisticated production lines that can be economically justified when the flows to be processed are large. The Green Wave works even when the flows are limited.

VIDEO: Green Wave a revolution in production planning

Stable Plans, Greatly Reduced Lead Times, and Work-in-Progress with Onde Verte®

Too good to be true? It’s even more beautiful than that in reality. Green Wave scheduling makes it possible to build long-term production plans (6 months) that will not need to be retouched except in the event of a major incident. A major incident is an “abnormal” breakdown of the production unit, or an “abnormal” demand. Here, “abnormal” is understood as more than 2 or 3 standard deviations from what one would usually expect.

The promises of this new scheduling method are very shortened production times, work in-process divided by 3 or 4, a drastic reduction in the working capital (the company’s cash requirement) and a stable schedule guaranteeing quality and regular supplies.

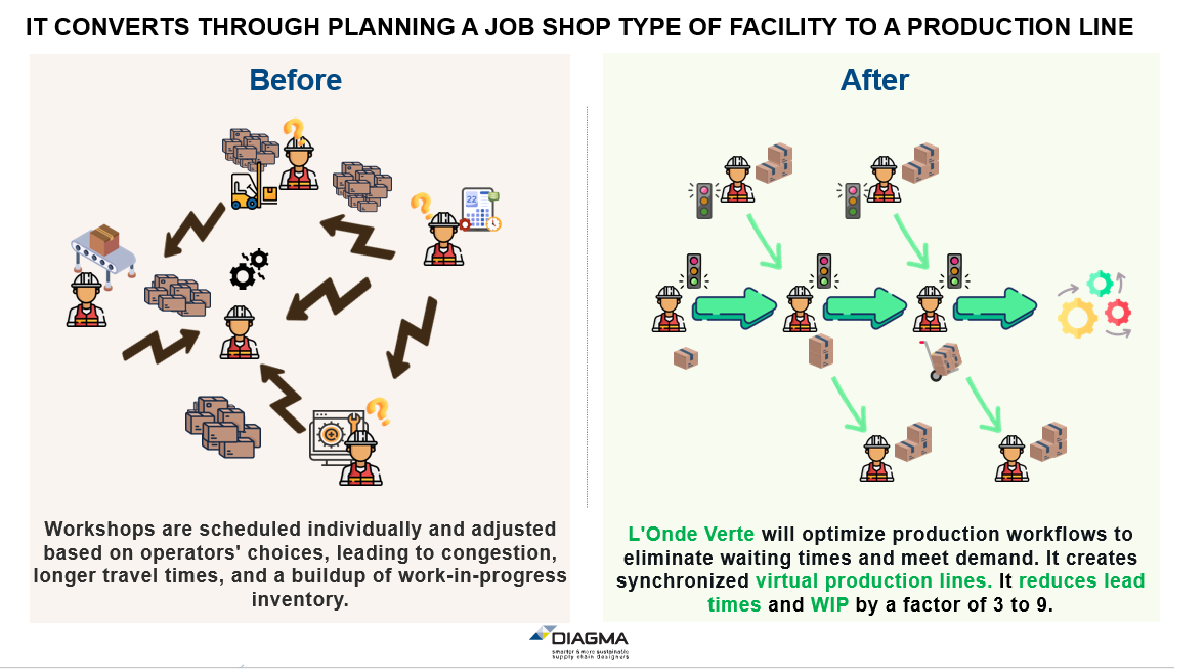

Building Virtual Paced Production Lines in a Job Shop

When does this method apply? In a way, it is a question of building virtual cadenced production lines. This is therefore only of interest if it is a production method with several steps that are not necessarily coordinated from the outset. For example, a passage through workshops or equipment where one chooses or not to produce a so-called “economical” batch in one go.

This is the case, for example, with the batch production of a semi-finished product (a tank of perfume for example) and then its continuous packaging. This is the case in Chemistry or Pharmacy where reactions are carried out that take a certain amount of time, or the passage in batch through ovens with a rise in temperature, stabilization for a few hours and then a controlled descent (casing for “the electric and electronic heart of airplanes for example). This is what is known in English as a “job shop”, a production through successive specialized stages. This is the case for mechanics with machining, milling, stamping, etc.

On the other hand, putting a production that is already in line on a cadenced line does not make sense to reduce work in progress. There is no need to synchronize the manufacturing of everyday consumer products in high demand. They are already manufactured on production lines.

A Gain in Quality and Predictability

On the other hand, green wave planning brings a stable procurement plan to suppliers. And this is always welcome for reliability of procurements and quality of production. Contrary to the usual practices of MRP methods, the production and supply plan (at the technology family level) is only updated episodically (once every 3 to 6 months is a good rhythm). This stable and predictable plan makes it possible to increase and make reliable all production standards (rates, changeover times) by doing them repetitively in the same time slots. Quality improves, suppliers are at peace, and able to organize manufacturing and delivery.

The Success of Onde Verte®

What progress has been made recently on the Green Wave concept? The method has been applied to the so called “long-molecule” pharmaceutical industry (vaccines for example) with a division by 12 of the Working Capital Requirement and with a 20% increase in production capacity. In the smelting industries (glass, steel) the lead times and work in progress have been divided by 10, in the mechanical industries (divided by 3), in the industries with manufacturing and packaging (the manufacture and packaging of perfumes for example) the need for vats has been divided by 3.

As for application software such as Google AI’s for the green wave in the city, we are making progress. For the time being, the Green Wave requires consultants in the initial analysis phase and simulation phase. From our experience, building a green wave in an industry requires 6 months. It has always been worth it.

Jean-Patrice NETTER

Founder & President DIAGMA